Answers

Below are answers to many frequently asked questions regarding the operation, maintenance, and design of our boat lifts. Please call us if you have any specific questions that have not been answered below.

Q. What Safety Precautions need to be followed when operating my boat lift?

A. READ ALL SAFETY INSTRUCTIONS BEFORE OPERATING BOAT LIFT:

CAUTION: Boat lifts are NOT designed to be used for lifting people or transferring people, or for lifting objects above people or above areas occupied by people.

1. Never operate the boat lift with people in, on, or under the watercraft or the lift. Boat lifts are not intended for human lifting. No person should ever be in, on, or under the watercraft while suspended on the boat lift.

2. Always inspect the boat lift for damage to beams, cables, belts, sheaves and other components prior to operation.

3. Always keep hands and clothing away from moving parts of the boat lift.

4. Always guide the watercraft on or off of the boat lift by hand with lines/ropes, using the guide posts to position the watercraft on the cradle and between the cables at the correct lifting point(s).

5. Always re-adjust the center of gravity whenever there is a change in weight distribution on the boat. Reposition the boat on the lift so that the load is evenly distributed to all cables. Make sure that the lift has been properly adjusted for the specific boat that is being lifted. Never overload the boat lift or any of its components.

6. Never walk away from the boat lift during operation. Do not allow yourself to be distracted while the boat lift is in use. Failure to turn off the boat lift can result in serious damage and/or possible injury.

7. Never allow the boat lift to be operated by any person under the age of 18 years old. Any person operating the boat lift should always read safety instructions and understand the Owner's Manual before use.

Q. How do I operate my boat lift properly?

A. READ ALL OPERATING INSTRUCTIONS BEFORE USING BOAT LIFT:

Raising boat out of water:

1. Unload people and gear with boat in water (prior to lifting boat) instead of on boat lift.

2. Set boat lift controls to “DOWN” position and lower cradle far enough into the water to allow boat to be pulled into slip. Never let cradle hit bottom and lose cable tension.

3. Set boat lift controls to “OFF” position once cradle has been lowered sufficiently to allow boat to be pulled into slip. Do not allow cradle to hit bottom and lose cable tension.

4. Guide boat into slip by hand using lines/ropes secured to boat. Guide posts will center boat over bunks/chocks. Most of boat hull will overhang beyond front of lift when boat is balanced. The center of gravity of the boat MUST be positioned over the center of the boat lift. Never lift an unbalanced load with boat lift.

5. Set boat lift controls to ''UP" position and raise boat to desired storage height out of water. Cradle should not be raised significantly higher than dock or seawall cap level.

6. Set boat lift controls to "OFF” position. Do not allow cradle to hit top of boat lift.

7. Ensure that bilge pump in boat is on automatic setting. Significant water accumulation in boat may overload boat lift and result in serious damage and/or possible injury.

8. Turn off electrical power to boat lift when not in use for safety and security.

Lowering boat into water:

1. Ensure that boat drain plug(s) are in place before lowering boat into water.

2. Set boat lift controls to “DOWN” position and lower cradle far enough into the water to allow boat to be pulled out of slip. Never let cradle hit bottom and lose cable tension.

3. Set boat lift controls to “OFF” position once cradle has been lowered sufficiently to allow boat to be pulled out of slip. Do not allow cradle to hit bottom and lose cable tension.

4. Guide boat out of slip by hand using lines/ropes secured to boat.

5. Load people and gear into boat with boat in water instead of on boat lift.

6. Raise boat lift cradle out of water for storage while boat is in use. Galvanic Corrosion / Electrolysis can occur when cradle is in the water.

7. Turn off electrical power to boat lift when not in use for safety and security.

Q. How do I maintain my boat lift properly?

A. READ ALL MAINTENANCE INSTRUCTIONS BEFORE OPERATING BOAT LIFT:

Regular maintenance and lubrication are necessary to keep your boat lift operating properly and safely.

1. To keep your boat lift operating properly and minimize service calls, we recommend that you operate your lift regularly, even when your boat is not in use. Simply run the lift for approximately one minute in each direction. This will keep the motor contacts and brushes clean and the pulley(s) and bearing(s) lubricated.

2. Visually inspect all working components before each use for signs of wear or damage.

3. Check and tighten all nuts and bolts periodically.

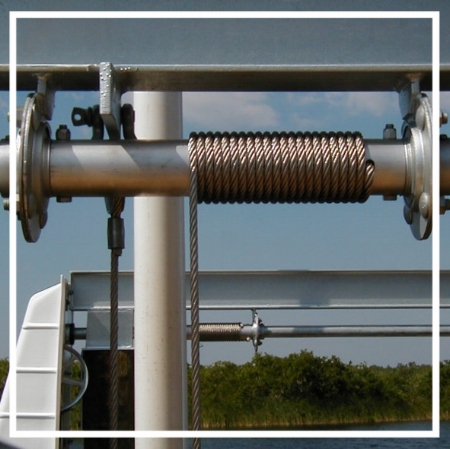

4. Inspect cables for any broken strands (cable fraying) or corrosion. Lubricate cables periodically with a light spray oil to reduce chafing and extend cable life. If cable fraying or corrosion is noticed, notify your dealer that your cables need to be replaced. Galvanized or Stainless Steel cables do not have an indefinite life span and must be replaced periodically. We recommend yearly cable replacement as preventative maintenance, though actual cable life will vary by location, maintenance, and usage. Care should be taken to ensure that cables wind up on the spool properly. Do not allow cables to lose tension and overlap on the spool. If cable clamps are used, check and tighten them at each inspection.

5. Gear units should be inspected / tested monthly. Lubricate the (3) grease fittings and gear teeth on each flat plate winch. A high temperature / marine-grade lubricant should be used.

6. Lubricate the grease fittings on the cradle (lifting) beams.

7. Rinse cables and cradle with fresh water after every use to prevent corrosion.

Q. What is a "No-Maintenance" boat lift?

A. Many boat lift manufacturers market some of their products as “No-Maintenance” boat lifts. When they make this claim, they are basically referring to the gear systems. “No-Maintenance” gears are fully-enclosed and sealed gearboxes that lack any external lubrication points. The gearbox manufacturers claim that you will not have to change the grease in these gearboxes within the warranty period (usually 5 years or less). They are not designed to allow any of the internal parts to be replaced in the field when something breaks. Their life expectancy is significantly less than that of the Flat Plate gear unit, which has a proven track record of durability over the last 50+ years.

Even if you purchase an enclosed gearbox, you will still have to perform regular maintenance on the remainder of the boat lift. You will need to have a grease gun to lubricate all of the bearings and sheaves on the lift. You will also need to inspect the cables regularly and lubricate them periodically with a light oil to maintain them and extend their lifespan. Ultimately, “No-Maintenance” really means that you can’t fix it when something goes wrong. You just throw the entire gearbox away when it breaks and buy a new one. This information is frequently omitted by boat lift manufacturers and/or installers when they are trying to sell their products. We believe that you should have all of the facts before you decide which boat lift system is going to work best for you for the entire time that you own it.

Dolphin Boat Lifts, Inc. makes boat lifts for the harshest saltwater environments imaginable. We build boat lifts that can be serviced, repaired, and, yes – our lifts require you to grease them. There is not a mechanical device in existence that does not require some sort of lubrication. The idea that you are going to install a mechanical device in a saltwater environment, dunk it in and out of the water and expect it to have any kind of service life without some sort of protective lubricant is absurd. GREASE IS YOUR FRIEND!

We have been building boat lifts for over 30 years. There are certain parts of your boat lift that need grease, and there are parts that do not. We only install grease fittings where you absolutely need them. And we absolutely recommend that you periodically fill them with grease to keep everything working properly.

Q. What makes Dolphin Boat Lifts better than the competition?

A. We overbuild our lifts to ensure that they will be able to safely lift the entire capacity for which they are rated. On many of our models, we use heavier beams than our competitors for boat lifts of the same capacity rating. All of our boat lifts are equipped with structural Cross Braces that tie the two Cradle Beams together to prevent them from twisting in opposite directions. You will notice that most of our competitors omit these structural components in order to cut costs. We go the extra mile to ensure that you get all of the lifting capacity for which you are paying, as well as the longest possible service life.

The same principle applies to our gear units. We design our boat lifts to comfortably lift the intended load without overloading the gear units. Many of our competitors are very aggressive with their gear configurations in order to reduce costs or increase lifting speed, with the end result being a much shorter service life and less reliability. We understand that you need your boat lift to be dependable for the entire time that you own it.